Renault Sandero Workshop Manual (2012-2016)

$9.99

The official Renault Sandero Workshop Manual (2012-2016) is your ultimate repair and maintenance guide. With over 3,500 pages of factory-approved instructions, this manual covers petrol and diesel engines, automatic and manual gearboxes, and more. Ideal for professionals and DIY car owners.

Description

Renault Sandero Workshop Manual (2012-2016)

Comprehensive Renault Sandero Workshop Manual

Get access to the official workshop manual for Renault Sandero (2012-2016) – the same resource used by authorized service centers and manufacturers to build and repair your vehicle! Perfect for professionals and DIY enthusiasts, this manual ensures precise and accurate repairs.

Key Features

- Manufacturer-Approved Content: Trusted by Renault service professionals.

- Complete Technical Information: Covers petrol and diesel engines, LPG systems, manual and automatic transmissions, suspension, and more.

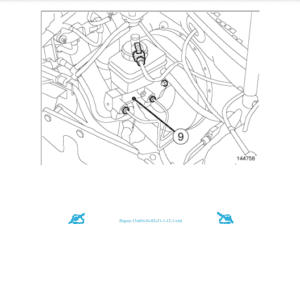

- Over 3,500 Pages: Step-by-step repair instructions with detailed illustrations.

- Language: English.

Applies to Renault Sandero Models

- Years: 2012, 2013, 2014, 2015, 2016.

- Engine Types: Petrol, Diesel.

- Transmissions: Manual, Automatic.

What’s Inside?

This manual includes everything you need to know, from maintenance to complex repairs:

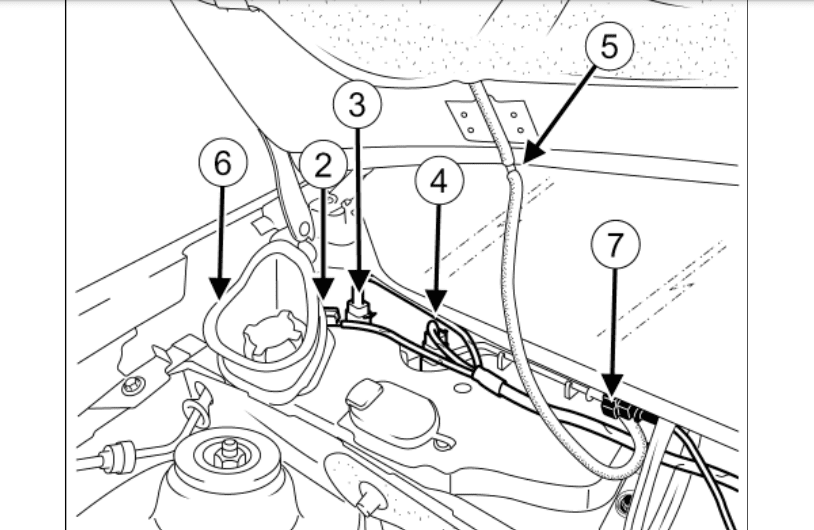

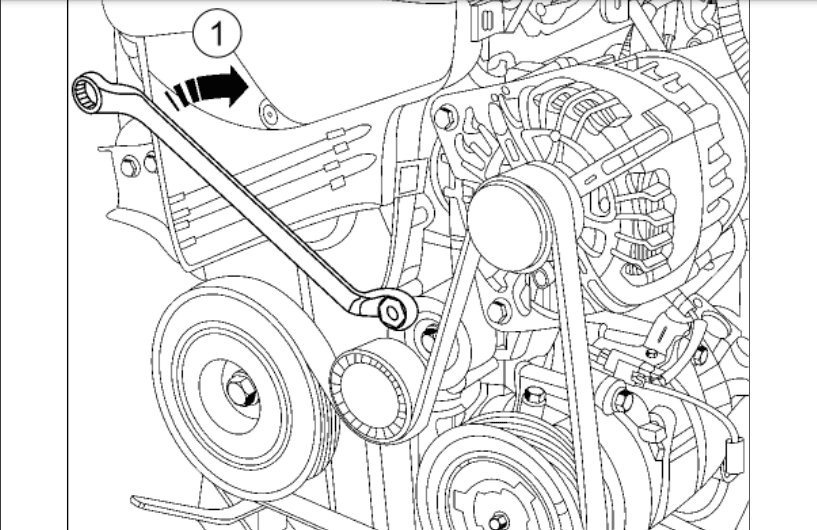

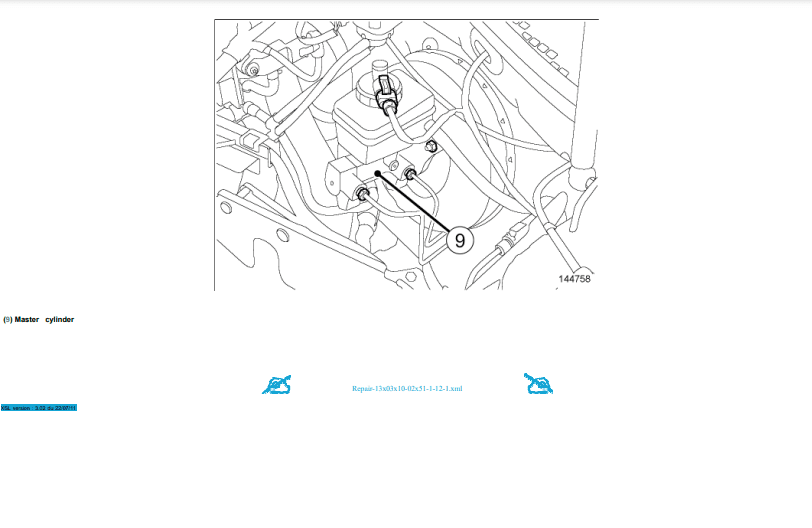

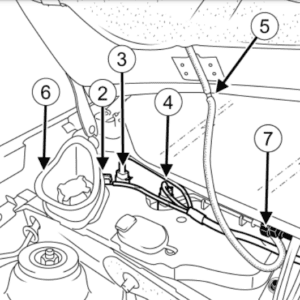

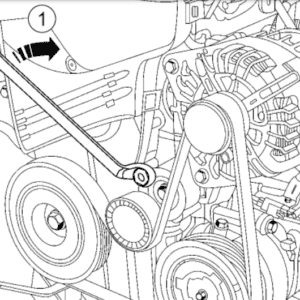

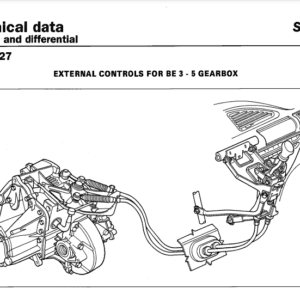

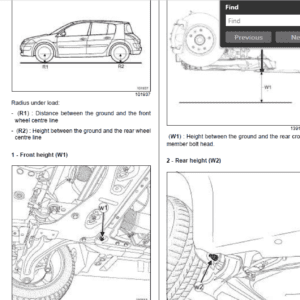

- Detailed diagrams and wiring layouts.

- Procedures for engine, gearbox, suspension, and brake repairs.

- Air conditioning system diagnostics and servicing.

- Bodywork repair techniques and anti-corrosion treatments.

- And much more, covering over 3,500 topics.

Highlights from the Table of Contents

- Engine Repairs: Crankshaft pulley removal, oil filter replacement.

- Brake Systems: Circuit bleeding, servo removal, ABS troubleshooting.

- Body & Trim Work: Paint touch-ups, bumper replacements, corrosion protection.

- Transmission Services: Gearbox adjustments, clutch pedal repairs.

- Electrical Systems: Wiring repairs, alternator removal, lighting system troubleshooting.

Why Choose This Renault Sandero Manual?

- Reliable: Direct from Renault’s official resources.

- User-Friendly: Clear, detailed instructions with easy-to-follow visuals.

- Comprehensive: Covers everything from minor maintenance to advanced diagnostics.

Upgrade your repair and maintenance capabilities with this essential workshop manual for the Renault Sandero. Stay confident in every repair job, knowing you’re using the same professional-grade manual trusted by authorized Renault service centers.

Start repairing smarter today!

Reviews

There are no reviews yet.